LumberOptimizer: How to mark your lumber (1 of 2)

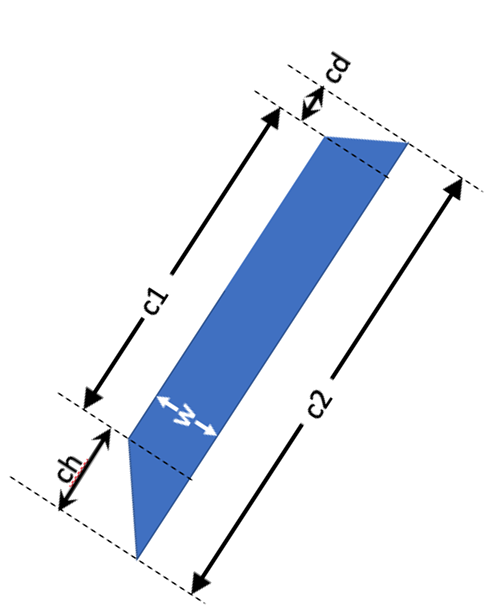

First, we need to appreciate the relationship

ch + c1 + cd = c2

where ch is the hypotenusal difference owing to the height of the diagonal support while cd is the difference owing to the depth of the support.

Second, we need to appreciate the basic geometry of a diagonal: From a given side of the lumber the cutlines are both either oriented inward or outward. In other words, the cutlines are oriented such that the diagonal resembles more of a trapezoid than a parallelogram.

Second, we need to appreciate the basic geometry of a diagonal: From a given side of the lumber the cutlines are both either oriented inward or outward. In other words, the cutlines are oriented such that the diagonal resembles more of a trapezoid than a parallelogram.

How to mark your lumber (2 of 2)

With the four values: ch, c1, cd and c2, we have all the numbers we need to mark our cutlines.

When we mark our cutlines, we should begin with the SMALLER of ch or cd.

Moving along the length of the lumber, separated by a c1, cd and ch alternate: E.g., cd-c1-ch-c1-cd-c1….

Because the width of the blade affects the cutlines, we recommend alternating between making a cut and marking a cutline. By marking a cutline based off a measurement from an actual cut, we avoid the need to have our cutlines account for the width of the blade and the angle of the cut.

When we mark our cutlines, we should begin with the SMALLER of ch or cd.

Moving along the length of the lumber, separated by a c1, cd and ch alternate: E.g., cd-c1-ch-c1-cd-c1….

Because the width of the blade affects the cutlines, we recommend alternating between making a cut and marking a cutline. By marking a cutline based off a measurement from an actual cut, we avoid the need to have our cutlines account for the width of the blade and the angle of the cut.

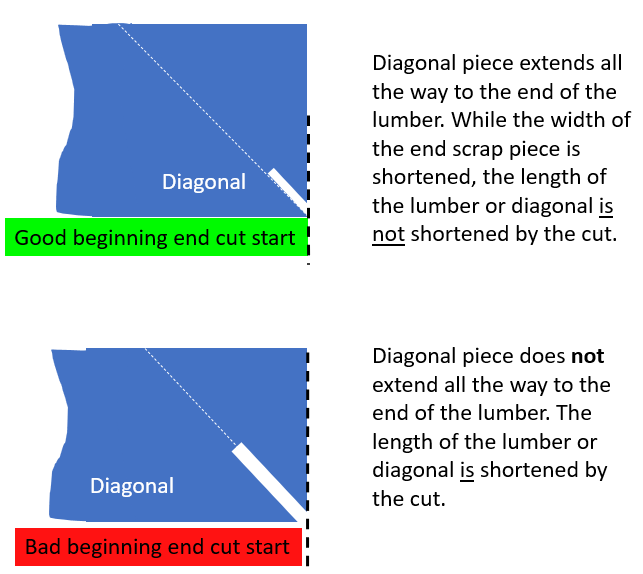

How to make the beginning endcut

(for the purists only! See note below.)

The beginning endcut occurs at the end of the lumber.

On the beginning endcut, the blade should be positioned such that it does not remove any of the length of the lumber.

If a beginning end cut positions the blade so that the length of the lumber is shortened by an endcut, then the last diagonal harvested will be smaller than the others.

On the beginning endcut, the blade should be positioned such that it does not remove any of the length of the lumber.

If a beginning end cut positions the blade so that the length of the lumber is shortened by an endcut, then the last diagonal harvested will be smaller than the others.

But if you specify the length of your lumber to be n/16 smaller than the actual length of the lumber, then you don’t have to worry about the perfect position of where exactly your blade width is relative to the cut line.

How to determine your bladewidth

There are different ways to determine the width of the blade

A new blade should have the packaging indicating the bladewidth

Sometimes the tooth side displacement can change with usage. On a circular blade the direction the teeth protrude can alternate and this can be difficult to measure directly.

Because of tooth spacing and the possible lack of a pair of calipers with deep and contoured jaws, the best way to determine your bladewidth could be to make a partial cut into a scrap piece of wood and measure the width.

A new blade should have the packaging indicating the bladewidth

Sometimes the tooth side displacement can change with usage. On a circular blade the direction the teeth protrude can alternate and this can be difficult to measure directly.

Because of tooth spacing and the possible lack of a pair of calipers with deep and contoured jaws, the best way to determine your bladewidth could be to make a partial cut into a scrap piece of wood and measure the width.